Products

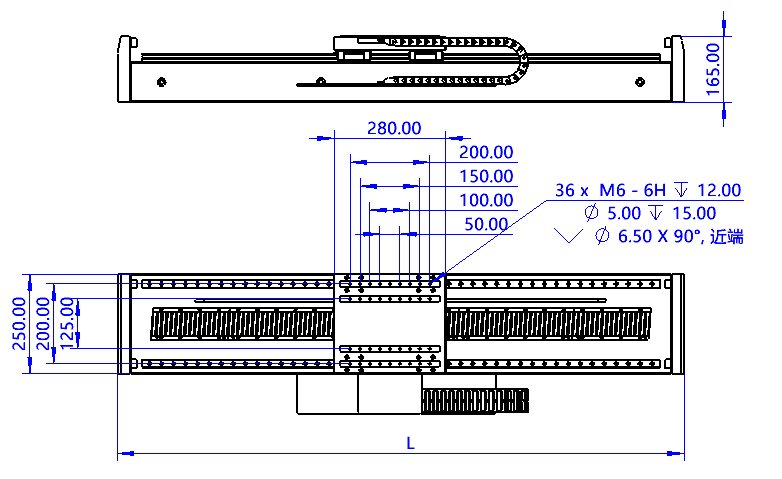

E-LMS250GT-X (linear positioning stage) One-dimensional linear motor motion stage

E-LMS250GT-X feature

● High-Speed Linear Stage • High Load Capacity • Linear Motor • Marble base • high rigidity, • high straightness • high precision;

● Long travel ranges (500 to 2000 mm) with narrow profile (165 mm width);

● Permanent load capacity to 3000N;

● Highly dynamic, maintenance-free linear motor with velocities up to 2 m/s;

● Robust industrial design for a long lifetime;

● High-precision incremental or absolute linear encoder;

● Marble base, high rigidity, high straightness, high precision;

● Linear Motor Stage High-Speed Linear Stage;

● High Load Capacity • Cost Effective • Linear Motor;

Industrial Design

Industrial design for high performance and high load

The E-LMS250GT-XX is a heavy-duty and highly dynamic linear stage for industrial applications. Its design is consistently geared to demanding industrial conditions and it is characterized by high stiffness and the use of high-quality components: recirculating ball bearing guides, 3-phase linear motor, incremental or absolute linear encoder. The high resolution of the encoders allows an excellent tracking performance, small tracking errors, and short settling times. Industry-compatible connectors offer a fast and secure connectivity.

Linear motor with direct drive

3-phase magnetic direct drives do not use mechanical components in the drivetrain, they transmit the drive force to the motion platform directly and without friction.

The drives reach high velocities and accelerations. Ironless motors are particularly suitable for positioning tasks with the highest demands on precision because there is no undesirable interaction with the permanent magnets.

This allows smooth running even at the lowest velocities and at the same time, there is no vibration at high velocities. Nonlinearity in control behavior is avoided and any position can be controlled easily. The drive force can be set freely.

Application fields

Electronics manufacturing: PCB manufacturing, printed electronics.

Test & inspection: Noncontact 2D measurement, sensor & camera placement for inspection, position sensor testing, vibration & acceleration testing.

Advanced manufacturing: Robotic manipulation and microassembly, industrial inkjet printing.

| Specification | LMS250GT-500X | -1000X | -1500X | -2000X |

| Effective distance [mm] | 500 | 1000 | 1500 | 2000 |

| Opticval Encode resolution [nm] | default 0.1um (Max 1nm optional) | |||

| Repeatability Accuracy [um] | ±0.3 | |||

| Accuracy [um] | 2um/100mm (less than 0.5um/100mm after calibration) | |||

| Flatness [um] | ±2.5 | ±5 | ±7.5 | ±10 |

| Straightness [um] | ±2 | ±5 | ±7.5 | ±10 |

| Max Speed [m/s] | 2 | |||

| Max Acceleration [G] | 4 | |||

| Max load capacity [kg] | 300 | |||

| L [mm] | 920 | 1420 | 1920 | 2420 |

1) What is “Nanopositioning”?

A: In the not-too-distant past, the precision tail-end of the bell curve in automation was often colloquially referred to as the “micropositioning” segment of the market. The term microposition derives from the fact that high-precision positioning systems were routinely operating at the micron level. Manufacturers in this space were specifying key system attributes such as Bi-directional repeatability, Accuracy, and Stability in units of microns. Such systems sufficiently filled industry demands from Life Science and Diagnostics, to Non-contact metrology, to the Tech sectors of Semiconductor, Data Storage, and Flat Panel Display.

Fast forward to our present day and no longer are such systems sufficient. Evolving industry needs in microscopy and biotechnology demand evolving levels of performance from precision positioning equipment manufacturers. As the features of interest across markets become smaller, the ability to position at the nanometer level becomes a market imperative.

2) Does your product ship overseas?

A: Yes, we ship our products internationally and have distributors in designated areas.

3) How do I ask for a quote on a specific product?

A:You can send a email to us , we will make a official quotation to you.

4) Are the products customizable?

A: We provide the ultimate engineered motion solutions for our clients. In many cases this involves customizing or configuring our standard products to a client’s unique application and specifications. Please contact us if you’re interested in customizing or configuring one of our standard products, or if you’d like to work with our engineering team to design a unique solution to meet your needs of the feedback source. If this velocity is exceeded, the commutation initialization is no longer valid, and commutation must be reinitizlized.

5)What is gantry stages?

A: The gantry stages are designed to provide unsurpassed repeatability and excellent throughput under real world operating conditions. Our gantry stages are designed to move such items as inspection cameras, laser heads, or specific customer tooling over either removable substrates or fixtures mounted to the base of the system. The gantry base can be provided with mounting holes for interfacing a customer’s hardware to the stage. Due to its simplicity and ease of assembly, it is the ideal gantry stage configuration for OEMS and system integrators building machines for demanding applications. Many of Dover Motion’s standard screw driven and servo motor linear products can be integrated together as a gantry stage to achieve an application’s required accuracy and travel for XYZ motion.

●Pre-formatted base for ease of integration;

●Risers to provide space between the base and moving beam;

●Integrated cable tracks and hi flex cable;

●All axes tested together and burned in to ensure performance and reliability requirements are met before shipment.