-

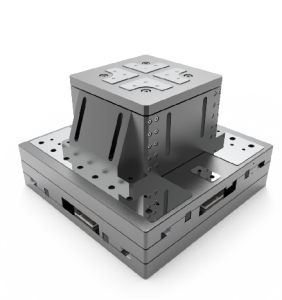

E-LMT-XYZ (high precision linear motor XYZ Axis stage

Elevation Stage with Excellent Straightness and Flatness of MotionThe vertical stage platform design provides excellent straightness and flatness, with better pitch and yawperformance compared to vertically mounted linear positioning stages, where the cantilevered load can causedeflections in the supporting linear bearings.High Resolution Linear Motion with voice Servo MotorsE-ABVT-Z is internally driven by a voice coil motor, equippedwith an air-floating transfer rail (cross ball guide rails can also be used), and uses a high-resolution grating to closethe loop, and is equipped with a high-performance driver to ensure the minimum displacement and repeatability ofthe positioning stage. achieve great performance.Computer Control, Software, Programming -

E-NFZ240-Z series (Z-axis high-precision linear motor stage)

● Design Features

● Designed for high-performance scanning and inspection

● Active air preload on all air-bearing surfaces

● Linear encoder feedback provides sub-nanometer resolution

● High stiffness for heavy loads and excellent geometrical performance

● with travels from 50 and 100 mm

● Integral counterbalance

-

E-LMT145-Z (High precision Nano Motorized Stage) Vertical Z axis Linear Motor Stage

● Design Features

● Designed for high-performance scanning and inspection

● Active air preload on all air-bearing surfaces

● Linear encoder feedback provides sub-nanometer resolution

● High stiffness for heavy loads and excellent geometrical performance

● with travels from 50 and 100 mm

● Integral counterbalance

-

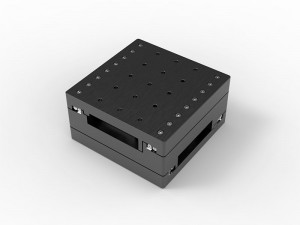

E-Linear motor stage and controller ELMT-MINIXY

ELMT-MINIXY series has extremely compact dimensions and excellent dynamic performance, especially suitable for those who are sensitive to space size, At the same time, it is hoped to have a larger stroke and higher precision application scenarios.

-

E-SST160-Z50 Z-axis stepper motor lifting table

● Vertical motion range 25 or 30mm

● min step to 100nm

● load capacity to 6 kg

● Direct-measuring linear encoder option

● Stepper motor drive

● cross ball rails

-

E-LMT-XY (High precisionLinear Motor Stage) XY Linear motor motion Stage

● Travel range 100 mm × 100 mm or 200 mm × 200 mm

● Unidirectional repeatability to 0.3 µm

● Ironless 3-phase linear motor

● Velocity to 500 mm/s Incremental

● linear encoder with 4.88 nm resolution

● Crossed roller guides

● Linear motors

-

E-ABVT-Z Vertical axis air bearing stage

● Vertical motion range 20 or 38mm (1/2″)

● Positioning repeatability to 10nm

● load capacity to 6 kg

● Direct-measuring linear encoder option

● Voice motor drive

● Air bearing rails, cross ball rails can also be used

-

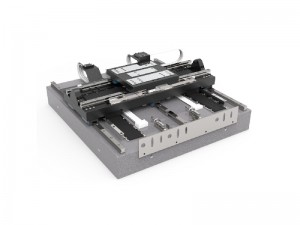

E-GLMT-XY (High Precision Linear Motor Stage) XY Linear motor stage

● Linear motors

● Linear motors are electromagnetic direct drives. They dispense with mechanical components in the drivetrain and transfer the drive force directly and friction-free to the motion platform. The drives reach high velocities and accelerations. Ironless motors are particularly suitable for positioning tasks with the highest demands on precision because there is no undesirable interaction with the permanent magnets. This allows smooth running even at the lowest velocities and at the same time, there is no vibration at high velocities. Nonlinearity in control behavior is avoided and any position can be controlled easily. The drive force can be set freely.

-

E-TRI-R5 Three-axis parallel leveling platform

Parallel-kinematic design for three degrees of freedom, making it significantly more compact and stiff than serial-kinematic systems, higher dynamics, no moved cables: Higher reliability, reduced friction.