Products

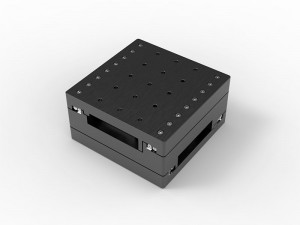

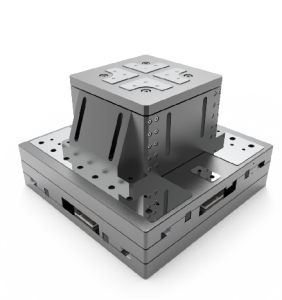

E-LMT-XY (High precisionLinear Motor Stage) XY Linear motor motion Stage

Linear motors are electromagnetic direct drives. They dispense with mechanical components in the drivetrain and transfer the drive force directly and friction-free to the motion platform. The drives reach high velocities and accelerations. Ironless motors are particularly suitable for positioning tasks with the highest demands on precision because there is no undesirable interaction with the permanent magnets. This allows smooth running even at the lowest velocities and at the same time, there is no vibration at high velocities. Nonlinearity in control behavior is avoided and any position can be controlled easily.

The drive force can be set freely

● Highly accurate position measuring with incremental linear encoder

● Noncontact optical encoders measure the position directly at the platform with the greatest accuracy. Nonlinearity, mechanical play or elastic deformation have no influence on the measurement. Further travel ranges on request.

Crossed Roller Guide

With crossed roller guides, the point contact of the balls in ball guides is replaced by line contact of the hardened rollers. Consequently, they are considerably stiffer and need less preload, which reduces friction and allows smoother running. Crossed roller guides are also distinguished by high guiding accuracy and load capacity. Force-guided rolling element cages prevent cage creep.

Application Fields

Medical industry. Laser cutting. Scanning. Biotechnology. Metrology. AOI (Automatic Optical Inspection). Laser marking.

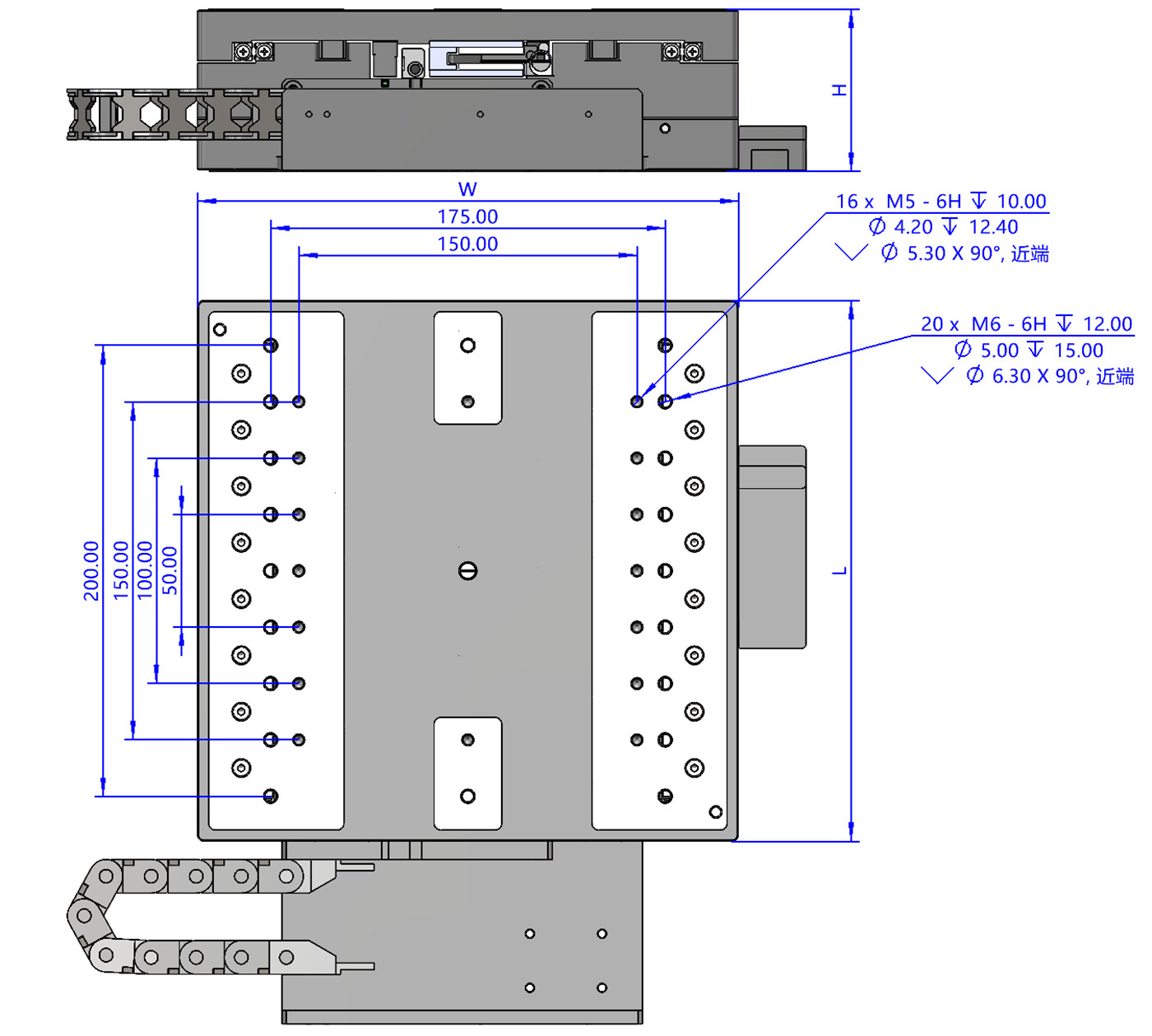

| Specification | LMT-XY-100X100 | -200X200 |

| Motor type | Three-phase ironless motor | |

| Opticval Encode resolution | sincos 4.88nm(Other higher resolutions are optional) | |

| Motor thrust | Continuous 40N/peak 90N | Continuous 60N/peak 210N |

| min step size[nm] | 10nm (with nanopwm or linear driver) | |

| Travel [mm] | 100×100 | 200×200 |

| Repeatability Accuracy [um] | ±0.3 | |

| Accuracy [um] | ±1 | |

| Flatness [um] | 6um | 8um |

| Straightness [um] | 1um | 1.5um |

| Max Speed [mm/s] | 500mm/s | |

| Max load capacity [kg] | 15kg | 30kg |

1) What is the MOQ?

A: MOQ is 1 pcs.

Sample is available for customer to check the quality before bulk order.

2) Do you accept OEM?

A: Yes, OEM and ODM is warmly welcomed.

It is our company’s strength, we can customize the LCD monitor so that can fully meet customers’ requirements.

3) What payment methods does your company accept?

A: T/T, Western Union, Paypal and L/C.

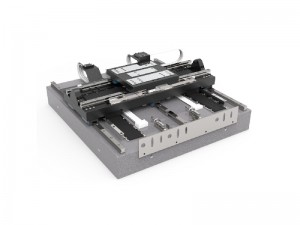

4)What is gantry stages?

A: The gantry stages are designed to provide unsurpassed repeatability and excellent throughput under real world operating conditions. Our gantry stages are designed to move such items as inspection cameras, laser heads, or specific customer tooling over either removable substrates or fixtures mounted to the base of the system. The gantry base can be provided with mounting holes for interfacing a customer’s hardware to the stage. Due to its simplicity and ease of assembly, it is the ideal gantry stage configuration for OEMS and system integrators building machines for demanding applications. Many of Dover Motion’s standard screw driven and servo motor linear products can be integrated together as a gantry stage to achieve an application’s required accuracy and travel for XYZ motion.

●Pre-formatted base for ease of integration;

●Risers to provide space between the base and moving beam;

●Integrated cable tracks and hi flex cable;

●All axes tested together and burned in to ensure performance and reliability requirements are met before shipment;