Products

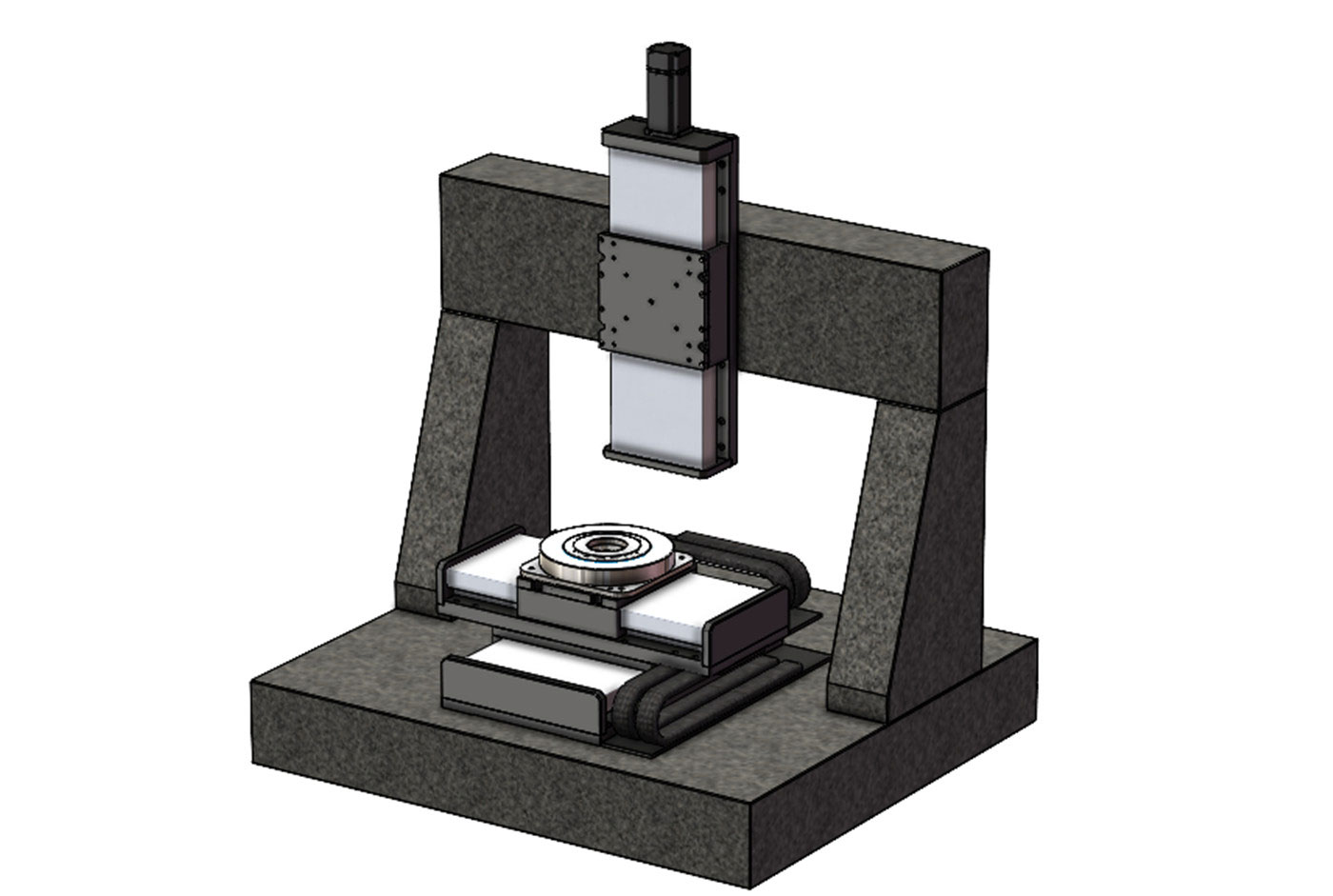

E-SCAN series of products SCAN -1 Nano Scanning Stage

Main Features of μSCAN Series

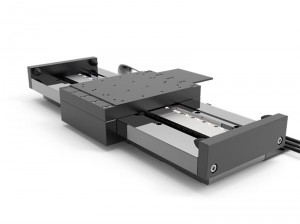

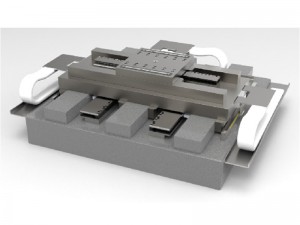

XY axis is composed of U1 series high-performance linear motor platform (labyrinth seal has good protection effect and no wearing parts and dust)

The R-axis is a high-precision flat DD motor

The Z-axis is equipped with U3 series high-precision servo motor platform (optional NFZ240 high-performance linear motor platform)

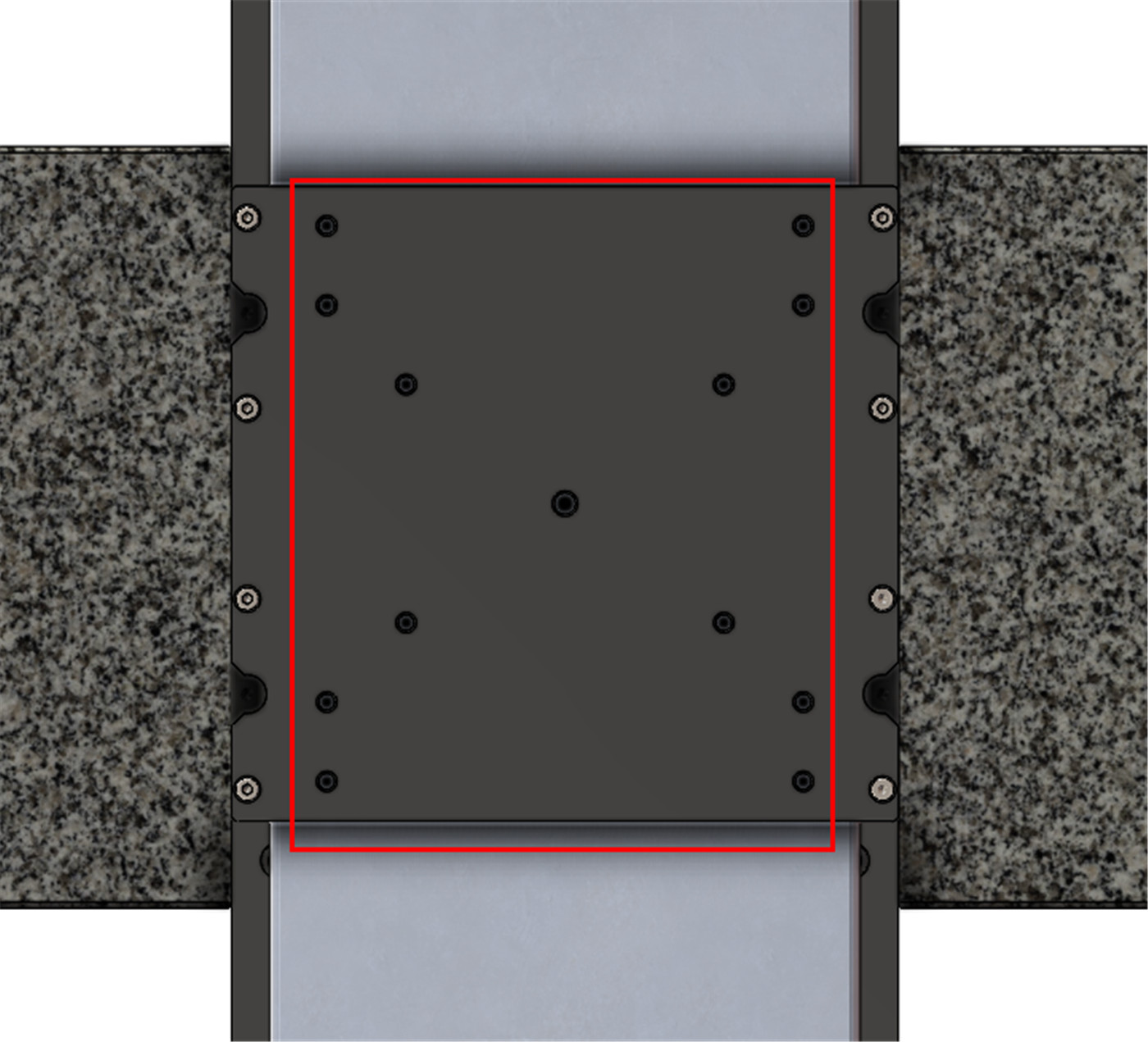

The base is made of high-performance stone such as Jinan Blue or Indian Black, and the precision can be selected from 0 or 00

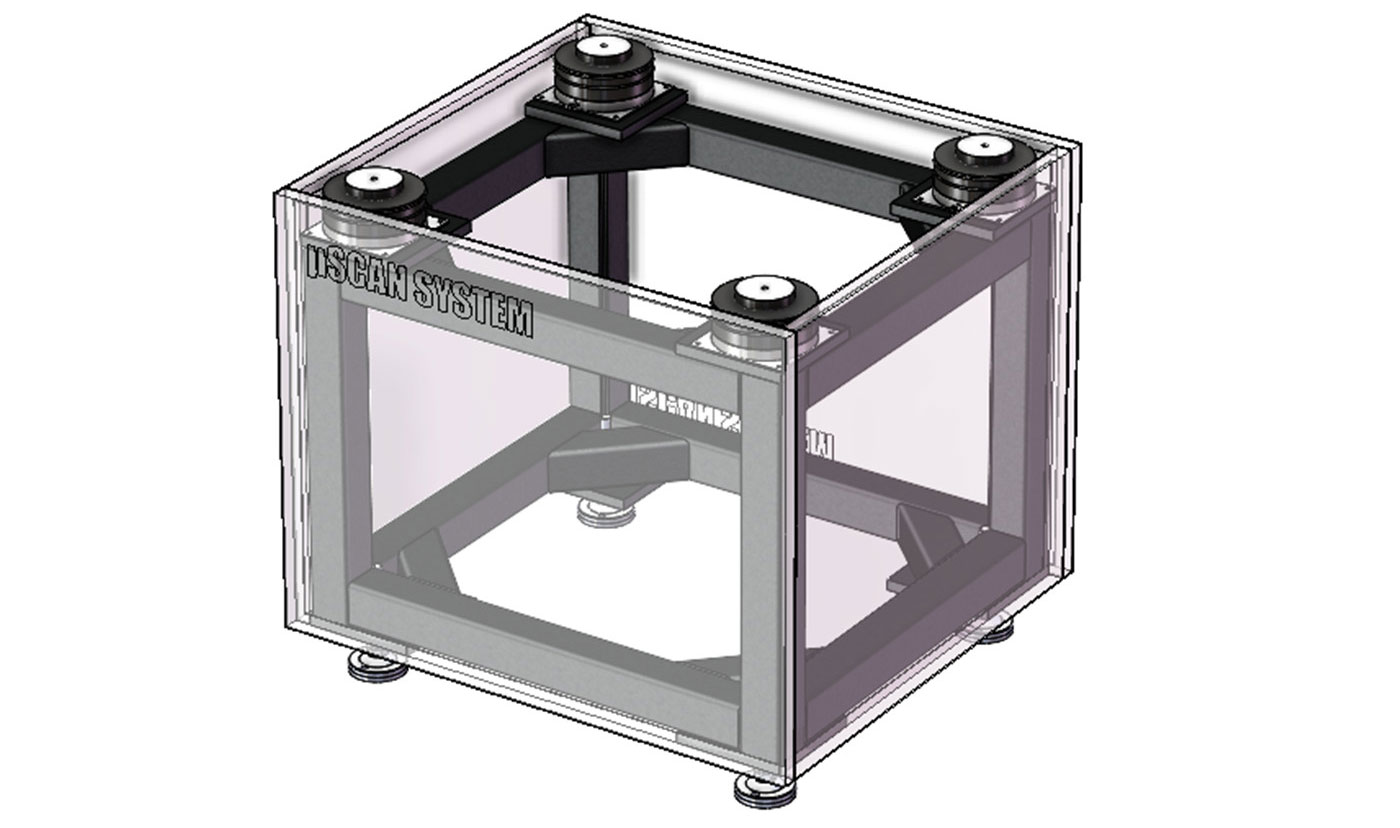

Frame and vibration isolation system can be selected according to application requirements

The XY motion system is optimized to support fast start-stop and continuous tuning applications (10kg load, 2mm stroke motion plus tuning <30ms (movement time 20ms, settling time 5-8ms))*1

● *1 Rapid start-stop movement has high requirements on drive control and parameter setting, please consult the manufacturer for details

● *2 The maximum speed is related to the stroke size, load and drive control system, please consult the manufacturer for specific requirements on speed

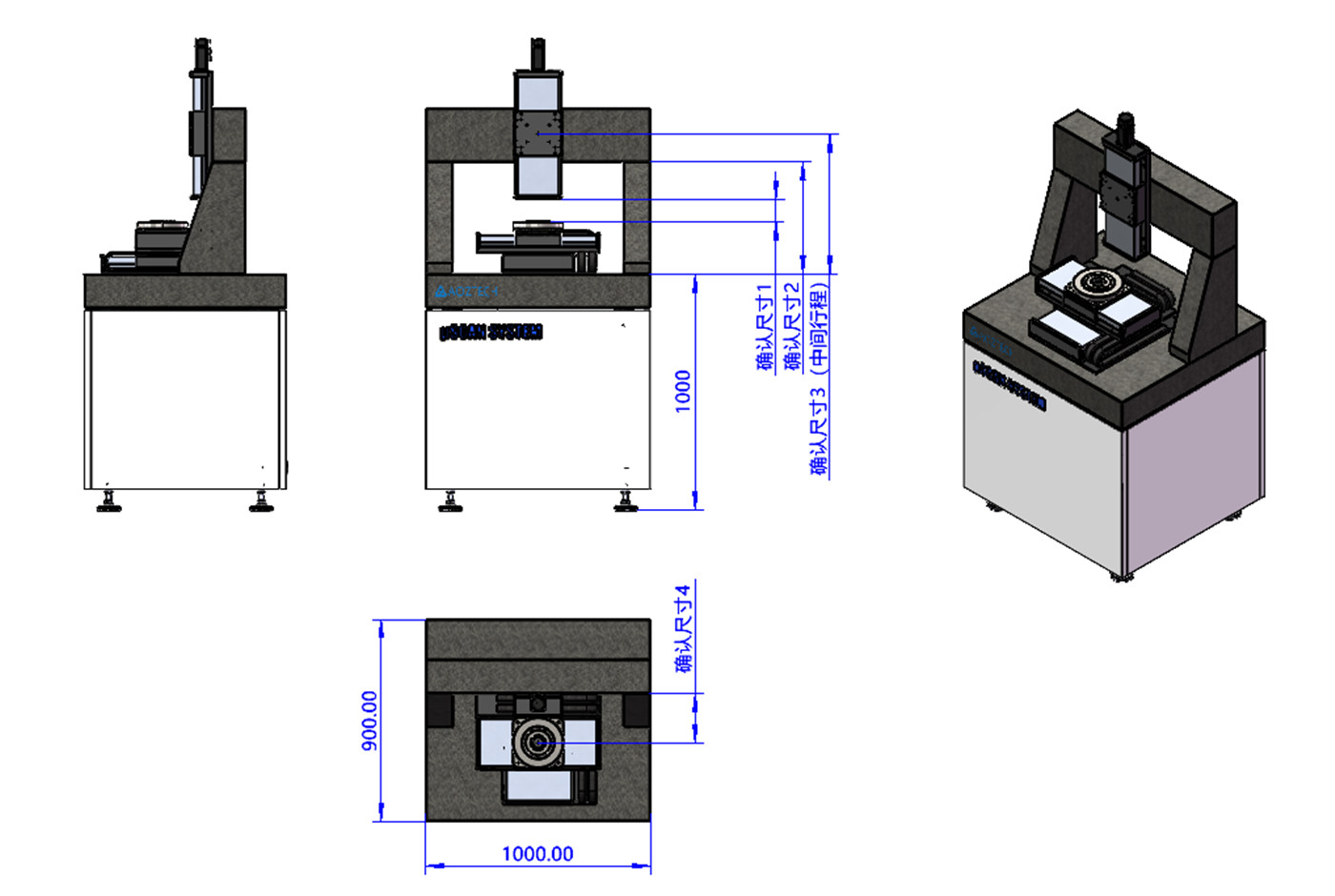

Precautions for size confirmation

Marble countertop length and width 1000x900x150 fixed size

After confirming the itinerary, please check with the technology to confirm the size 1/2/3/4

If we do not need to provide the rack, we also need to provide marble hoisting holes and screw mounting holes

The screw holes on the slides of each axis can be processed according to customer requirements

Device body (Granite must be selected: the size of the granite table is fixed for all strokes, and the height is determined according to the Z-axis stroke)

Rack body (This item is optional: including the rack and vibration isolators

Number of axes(XYZ or XYZR)

Confirm Travel range

Confirm control system

Confirm the number and thickness of load cables

Confirm whether vibration isolation or not

Confirm whether a rack

Confirm Travel range

Y axes travel range:100/200/300/400

X axes travel range:100/200/300/400

Zaxes travel range:50/100/200/300

R axes travel range:360°

Confirm control system

2 kind of control system:

MCS-ZMC(good for point to point movement): Positive motion 4-axis bus controller + Gaochuang driver x4

MCS-ACS(Suitable for movement with trajectory planning): 4-axis master controller+ACS driver x3+ Panasonic Servo Driver

Confirm whether vibration isolation or not

The natural frequency is required to be below 10Hz to choose a foamed polyurethane vibration isolator The natural frequency is required to be below 3Hz to choose an air flotation vibration isolator

| Specification of axes | Y Axes | X Axes | R Axes | Z Axes |

| Model of Axes | U1LM320-XX | U1LM240-XX | DDR224 | U3SVM210-XX |

| Travel range | 100/200/300/400 | 100/200/300/400 | 360° | 50/100/200/300 |

| Incoder resolution | 100nm | 100nm | 1sec | - |

| Repeatability | ≤1um(±0.5) | ≤1um(±0.5) | ≤±1sec | ≤3um(±1.5) |

| Maximum speed*2 | 1000mm/s | 1000mm/s | 4rps | 200mm/s |

| Maximum load | 50kg | 30kg | ||

| Motor thrust | 220N/440N | 330N/660N | 20Nm | - |

| Flatness of motion | ≤±5um | ≤±5um | ≤5um | ≤±5um |

1)Are you a factory or trading company?

A: We are a factory located in China.

2)How long is the warranty time for your products?

A: Warranty time is one Years.

3)Do you provide customized product service?

A: Yes, we can provide, we can design and produce according to the size, thickness and structure you want.

4) Are the products customizable?

A: We provide the ultimate engineered motion solutions for our clients. In many cases this involves customizing or configuring our standard products to a client’s unique application and specifications. Please contact us if you’re interested in customizing or configuring one of our standard products, or if you’d like to work with our engineering team to design a unique solution to meet your needs of the feedback source. If this velocity is exceeded, the commutation initialization is no longer valid, and commutation must be reinitizlized.