Products

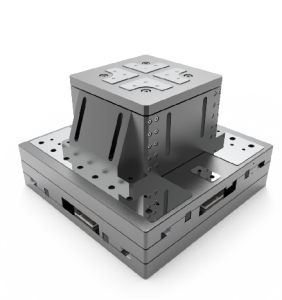

EG-DL130 Series of biaxial XY nanostages dual-axis XY positioning Stage which uses dual linear motors to drive the lower axis and a single linear motor to drive the upper axis.

The EG-DL130XY series is a two-axis integrated nano-positioning platform that utilizes advanced linear motor drive technology combined with a high-precision crossed roller guide design to provide users with superior nanometer-level positioning accuracy and stability.

The DL130XY series boasts a maximum horizontal load of 10kg, a maximum speed of 800mm/s, and a maximum no-load acceleration of 1g. Its compact dual-axis integrated design reduces overall space occupation, facilitating equipment layout in limited spaces and improving space utilization. All strokes feature a compact overall height of only 85mm, allowing for flexible customization based on customer applications. Applicable Scenarios: The EG-DL130XY series dual-axis XY positioning platform features high precision and high dynamic performance, making it suitable for the following scenarios: Semiconductor manufacturing such as photolithography and wafer inspection; Optical component manufacturing and laser processing; Precision machine tools and industrial robots; Applications requiring ultra-precision dynamic error control, such as optical waveguide processing and gene sequencing line scanning; Measurement and inspection, surface roughness detection, and ultra-precision laser processing, requiring nanometer-level positioning accuracy in industrial and research projects.

|

Model |

EG-DL130XY-60-60 |

EG-DL130XY-110-110 |

EG-DL130XY-160-160 |

| Travel |

60mm*60mm |

110mm*110mm |

160mm*160mm |

| Accuracy |

±250 nm |

±300 nm |

|

| Bi-Re peatability |

±100 nm |

±150 nm |

|

| Pitch |

10 arc sec |

12 arc sec |

15 arc sec |

| Yaw |

5 arc sec |

6 arc sec |

8 arc sec |

| Straightness |

±1.5 μm |

±1.75 μm |

±2 μm |

| Flatness |

±1.5 μm |

±1.75 μm |

±2 μm |

| Orthogonality |

5 arc sec |

||

| MaximumSpeed① |

800 mm/s |

||

| MaximumA cceleration① |

1.0 g |

||

| Continuous Fo rce |

24.2 N |

||

| Peak Force |

170.4 N |

||

| LoadCa pacity-Horizontal |

10 kg |

||

| Stage Mass(N o Motor) | 5.5 kg | 7.5 kg | 9.1 kg |

| Resolution |

1 nm |

||

| MinimumIncremental step② |

4 nm |

||

| InPosition Stability② |

±4 nm |

||

| Material |

Aluminium |

||

| MTBF |

30,000 Hours |

||

Notes: ① Maximum speed is under no-load conditions and requires an amplifier with appropriate power;

② Minimum step size and in-situ stability require high-performance feedback, such as an XC2e or XL2e linear amplifier;

③ The default test point position is 25 mm above the platform. This is a single-axis specification. Performance indicators for multi-axis systems depend on the actual load and operating point position;

④ Other travel distances can be customized.