Products

EG-DPLA SERIES dual-axis XY positioning hollow Stage uses dual linear motors to drive the lower axis and a single linear motor to drive the upper axis.

Product Description

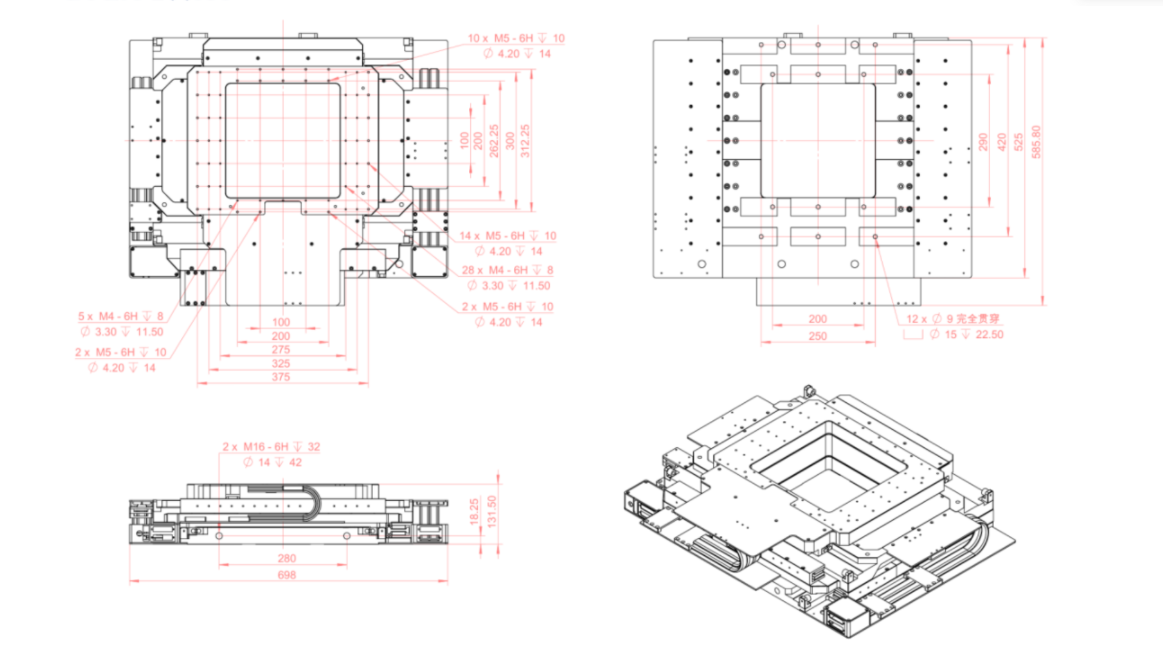

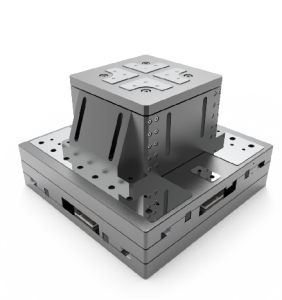

The DPLA-200XY is a dual-axis XY positioning hollow platform. Its lower axis is driven by dual linear motors, while the upper axis is driven by a single linear motor. Combined with a high-precision crossed roller guide design, it provides users with excellent positioning accuracy and stability. The DPLA-200XY has a maximum horizontal load of 25kg, a maximum speed of 200mm/s, and a maximum no-load acceleration of 0.2g. Flexible customization options are available to suit various customer applications.

Applicable Scenarios

The DPLA-200XY platform is a comprehensive hollow positioning platform that balances motion accuracy, long stroke, high dynamic performance, and strong load-bearing capacity. It can be applied to the following scenarios:

Optical inspection or multi-system collaborative operations

Biomedical fields such as gene sequencing, biological sample processing and observation, and automated sample processing

Fiber optic microsystem processing, double-sided measurement and inspection, and ink thickness measurement

|

MODEL |

EG-DPLA-200XY |

|

| Travel | 200mm*200mm | |

| Accuracy | ±300 nm | |

| Bi-Repeatability | ±150 nm | |

| Pitch | 10 arc sec | |

| Yaw-Single Motor | 9 arc sec | |

| Yaw-Dual Motors | 7 arc sec | |

| Straightness | ±1.75 μm | |

| Flatness | ±1.75 μm | |

| Orthogonality | 5 arc sec | |

| Maximum Speed① | 200 mm/s | |

| Maximum Acceleration① | 0.2 g (No load) | |

| Continu ous Force | Upper Axis | 112.1 N |

| Lower Axis | 224.2 N | |

| Peak Fo rce | Upper Axis | 651.5 N |

| Lower Axis | 1303 N | |

| Load Capacity- Horizontal | 25 kg | |

| Stage Mass(No Motor) | 35 kg | |

| Resolution | 1 nm | |

| Minimum Incremental step② | 3 nm | |

| In Position Stability② | ±3 nm | |

| Material | aluminum | |

| MTBF | 30,000 Hours | |

Notes: ① Maximum speed is under no-load conditions and requires an amplifier with appropriate power;

② Minimum step size and in-situ stability require high-performance feedback, such as an XC2e or XL2e linear amplifier;

③ Default test point position is 25 mm above the platform. This is a single-axis specification. Performance indicators for multi-axis systems depend on the actual load and operating point position;

④ Other travel distances can be customized.