Products

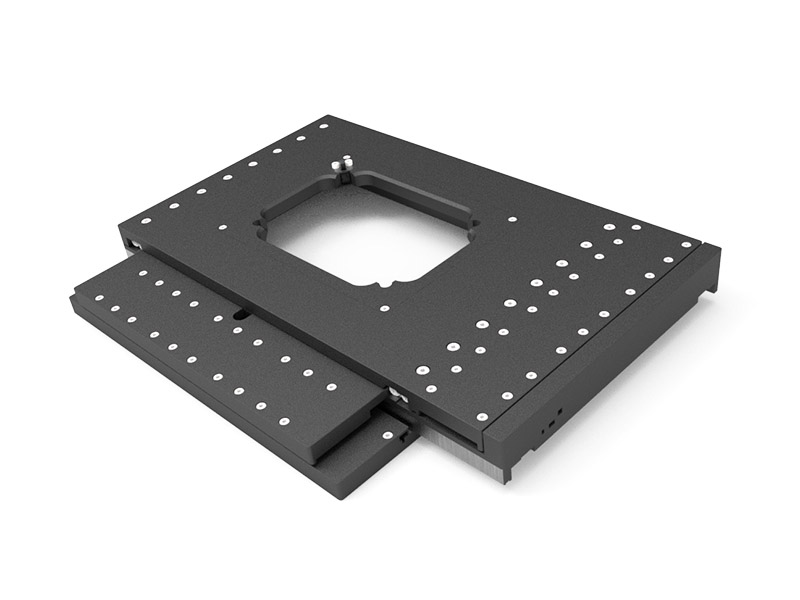

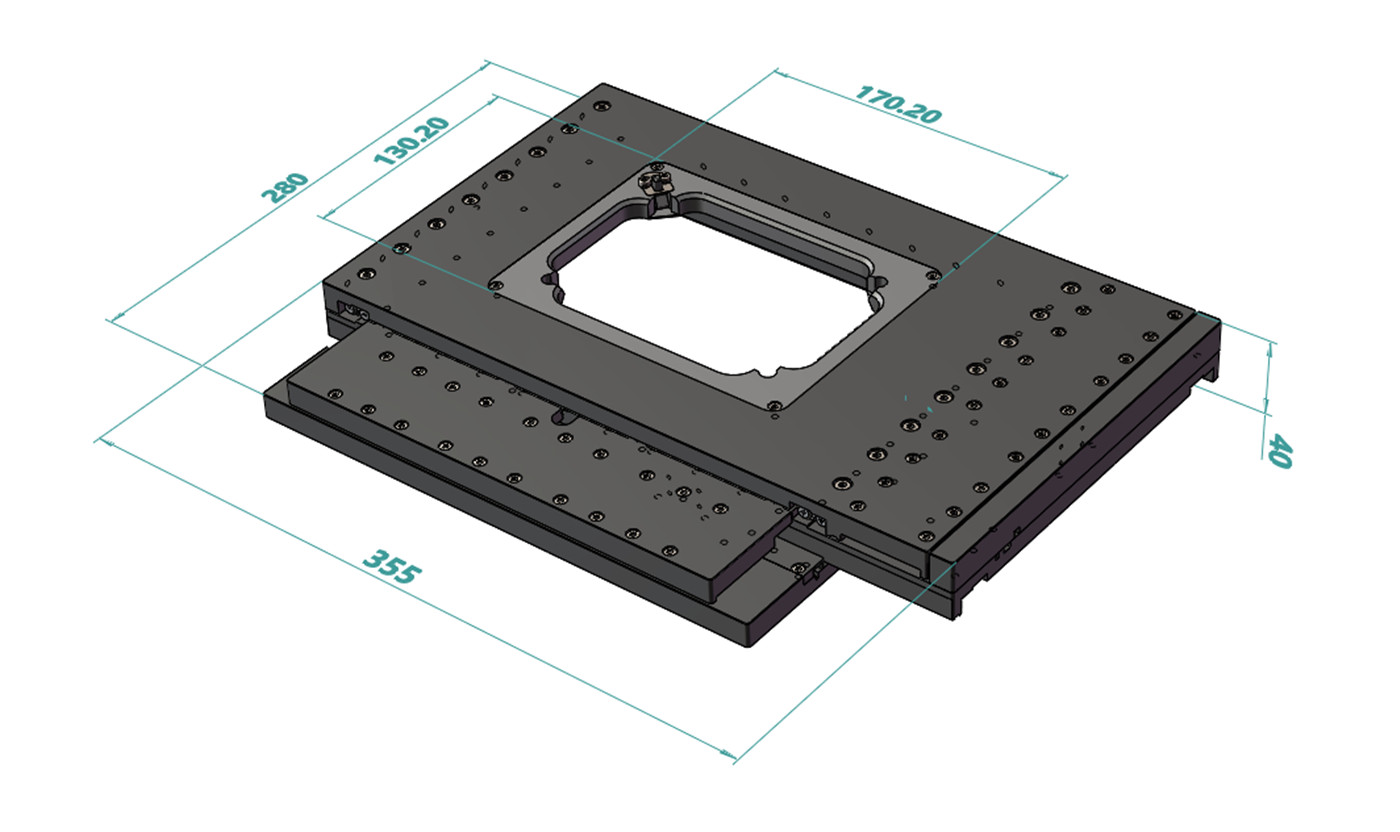

E-EMSLM-120X100-INXY-E50 Inverted Microscope Linear Motor Stage

Main Dimensions And Performance Parameters:

●Stroke: 120mm x 100mm

● Grating resolution: 50nm

●Minimum step size: 100nm

●Repeat positioning accuracy: ≤±250nm

●Maximum speed: ≥300mm/s

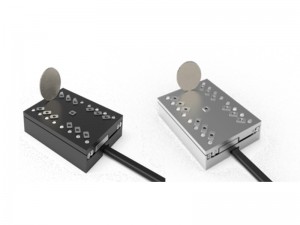

●Rail type: cross roller guide

●Maximum load: ≥5kg

●Direct drive mechanism, no backlash

●Main material: aviation grade aluminum alloy

●Surface treatment: sandblasting and hard anodic oxidation on the upper sliding table anodized, and the rest of the structural parts are generally anodized

Product Model Naming Rules

MSLM - 120X100 - INXY - E50

○1 ○2 ○3 4○

○1 MSLM is the English abbreviation of Linear Motor Microscope Platform

○2 100x100 represents the effective stroke of this type of product, in mm, if you need other strokes, you can contact the manufacturer to communicate and customize

○3 XY represents the direction and type of the working axis, and the default direction is confirmed according to the Cartesian coordinate system

○4 E50 represents the resolution of this type of product grating, the unit is nm, the default product resolution is 50nm, optional 20nm\100nm\0.5um\1um\5um etc. Changes in resolution will lead to changes in the maximum speed of the platform and repeat positioning accuracy. Please consult the manufacturer for details.

Special Attention Items

1. The linear motor platform is a high-precision precision equipment, so if you want to get the best performance, you need to ensure a sufficient operating environment, especially in On devices that require repeated positioning accuracy of less than 1um, the reproduction of all indicators needs to meet certain temperature, humidity, air pressure, vibration, etc. For detailed requirements, please contact the manufacturer for further consultation and communication

2. All platforms can be ordered separately. If the precision and performance requirements of the equipment are high, it is recommended to use the MCS controller series produced by ourselves. The products shipped by MCS series controllers will be optimized and calibrated in the factory inspection, which is your first choice for high-demand use.

1) What is “Nanopositioning”?

A: In the not-too-distant past, the precision tail-end of the bell curve in automation was often colloquially referred to as the “micropositioning” segment of the market. The term microposition derives from the fact that high-precision positioning systems were routinely operating at the micron level. Manufacturers in this space were specifying key system attributes such as Bi-directional repeatability, Accuracy, and Stability in units of microns. Such systems sufficiently filled industry demands from Life Science and Diagnostics, to Non-contact metrology, to the Tech sectors of Semiconductor, Data Storage, and Flat Panel Display.

Fast forward to our present day and no longer are such systems sufficient. Evolving industry needs in microscopy and biotechnology demand evolving levels of performance from precision positioning equipment manufacturers. As the features of interest across markets become smaller, the ability to position at the nanometer level becomes a market imperative.

2) Does your product ship overseas?

A: Yes, we ship our products internationally and have distributors in designated areas.

3) How do I ask for a quote on a specific product?

A:You can send a email to us , we will make a official quotation to you.

4) Are the products customizable?

A: We provide the ultimate engineered motion solutions for our clients. In many cases this involves customizing or configuring our standard products to a client’s unique application and specifications. Please contact us if you’re interested in customizing or configuring one of our standard products, or if you’d like to work with our engineering team to design a unique solution to meet your needs of the feedback source. If this velocity is exceeded, the commutation initialization is no longer valid, and commutation must be reinitizlized.

5)What is gantry stages?

A: The gantry stages are designed to provide unsurpassed repeatability and excellent throughput under real world operating conditions. Our gantry stages are designed to move such items as inspection cameras, laser heads, or specific customer tooling over either removable substrates or fixtures mounted to the base of the system. The gantry base can be provided with mounting holes for interfacing a customer’s hardware to the stage. Due to its simplicity and ease of assembly, it is the ideal gantry stage configuration for OEMS and system integrators building machines for demanding applications. Many of Dover Motion’s standard screw driven and servo motor linear products can be integrated together as a gantry stage to achieve an application’s required accuracy and travel for XYZ motion.

●Pre-formatted base for ease of integration;

●Risers to provide space between the base and moving beam;

●Integrated cable tracks and hi flex cable;

●All axes tested together and burned in to ensure performance and reliability requirements are met before shipment;